Follow us on LinkedIn

New dimensions of sustainable energy circular economy and decarbonization

FLD Technologies is a technology developer specializing in the generation, storage and transport of renewable energy. The goal is to ensure optimal use of resources and contribute to the energy transition by combining new and existing technologies. By using renewable resources (biogas, biomass), we enable the removal of CO2 from the air. This creates green hydrogen that can be used for a wide range of applications. By using recycled carbon and secondary raw materials, the circular economy is realized. With new dimensions of ‘power-to-gas’ (PtG), we address complex issues of energy storage and transportation.

Unique selling proposition

CO2 reduction: from climate neutrality to the negative footprint

Extreme scalability from local heating & industrial chemicals to long-distance transport

Generating green H2 with plasma pyrolysis

Using existing resources effectively

FLDT solutions

HyRegio® by FLDT

HyRegio® envisions the supply of hydrogen, electricity and heating/cooling to communities. To meet this requirement, H2 production is extended to include a local distribution system. During H2 production, the emitted CO2 is removed from the air. Learn more …

CML4® by FLDT

CML4® / CarboMethanLoop® adds a new dimension to the well-known power-to-gas (PtG) process. It enables energy transport over long distances as well as storage of green H2. Learn more …

FLDT Applications

Mobility

Hydrogen burns CO2-free. It is used, among other things, to generate electricity in fuel cells, which find application in car, truck drives. Mobility is the main application of the gas. Learn more …

Heating | Cooling

Green hydrogen can be used as a fuel for heating and for generating industrial process heat. The high combustion temperature of the H2/air mixture enables a wide range of applications with zero emissions. Learn more …

Electricity

Power generation could become one of the main applications of green hydrogen in the future, as fluctuating power generation with wind or photovoltaics can be compensated with H2-powered fuel cells. learn more …

Industry

Green H2 can be used as a product or raw material in the chemical industry. However, this does not exhaust the possibilities. Extended sector coupling opens up further solution options. learn more …

Partners

Patente

FLD Technologies has intellectual property rights.

CO2-neutral hydrogen circular economy on a global scale

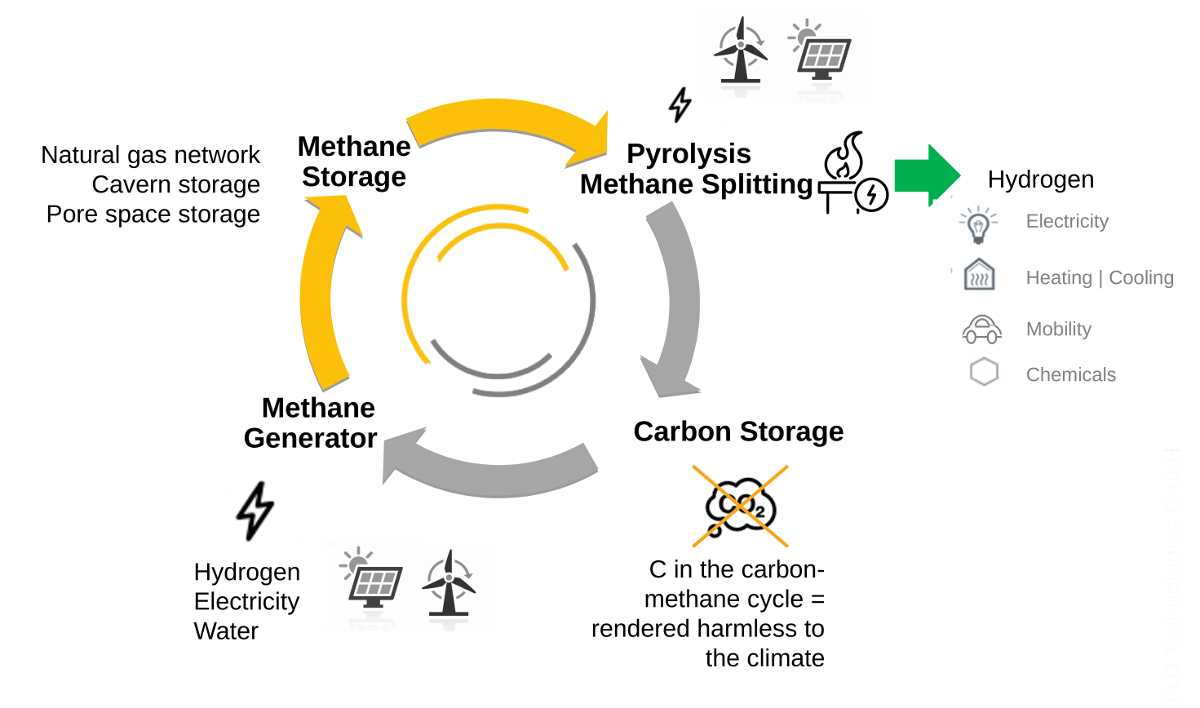

In the PtG process, methane is produced from renewable energies and CO2 and transported via gas grid — unlike CML4®. Here, methane is produced from renewable energies and from the carbon obtained in the pyrolysis. There is no need for the costly extraction of CO2 from the atmosphere. The carbon is considered a vehicle and is recycled. The energy carrier hydrogen is produced at the point of consumption by methane splitting. The H2 can now be used to generate electricity, heat/cold, for sustainable mobility or industrial chemicals. Thanks to the extremely power-saving and climate-friendly plasma pyrolysis, pure carbon alone remains to be used in the cycle as H2 carrier.

The carbon-methane cycle at a glance

Basic principle of the CML4® process from FLDT

Green hydrogen as the main energy carrier for future mobility

In the future, hydrogen will be the main energy carrier alongside electricity. It does not occur in pure form in nature and must be produced technically. It is a non-toxic, colorless and odorless gas. Hydrogen burns CO2-free. It is used, among other things, to generate electricity in fuel cells, which find application in car, truck drives. Mobility is the main application of the gas.

Heating/Cooling

Green hydrogen can be used as a fuel for heating and for generating industrial process heat. The high combustion temperature of the H2/air mixture enables a wide range of applications while remaining emission-free.

The thermal energy generated in the plasma pyrolysis process is also particularly valuable. Due to its high temperature, it can be used not only for heating but also for higher-value applications. Cooling by means of absorption chillers is also economically and commercially viable at this temperature level.

Green power

Electricity generation represents another application in both processes — HyRegio® and CML4®. In HyRegio®, electricity generation takes place in CHP units. The electricity can be fed into the power grid or used for the plasma process. The hydrogen produced in CML4® can be used directly to generate electricity. The combination of plasma pyrolisis and high-temperature fuel cells is particularly favorable here since the heat generated during pyrolysis promotes fuel cell operation. In both cases, the synchronization/stabilization of the power grids can be supported.

Raw materials for the chemical industry and further solution options

The CO2 obtained in biogas upgrading in HyRegio® processes can be called “green CO2” or bio-CO2 due to its biogenic origin. It can be used as a product e.g. in greenhouses or as a raw material in the chemical industry. The production of synthetic fuels represents another application option.

However, the possibilities do not end there. The CO2 captured from the air in the form of powdered carbon black, when immobilized, generates certificates that can be used to offset emissions from industries. Particularly in the case of production process in which CO2 emissions is product-related, compensation through certificates would be advantageous. Cement, steel and glass production and many more are conceivable here. Aviation could also be relieved.

Highly energy-efficient plasma pyrolysis with green electricity and no greenhouse gas emissions

Various hydrocarbons, e.g. biogas or CML4 methane, are split into solid carbon and hydrogen by plasma pyrolysis. The innovative reactor exposes the raw materials used to microwaves. It forms gas plasma. Electricity from renewable energy sources or biogas is used to generate the microwaves. To produce hydrogen, the process uses only a quarter of the electrical energy that would be required to produce the same amount of H2 in electrolysis.

Returning carbon as materialized CO2 or using it as an H2 storage medium in the circular economy

Unlike conventional CCS (Carbon (Dioxide) Capture and Storage) processes, our mGHGm® (Minimizing Green House Gases Measurably) method stores solid biocarbon geologically and permanently in the ground. Or we use it in our CML4® (Carbon Methane Loop) as a storage medium for green hydrogen for long-distance transport. Either way, none of our solutions involves forcing gas into cavities under pressure. By returning carbon to the earth or using it as storage, we achieve a very small to negative greenhouse gas footprint.

Extreme scalability: from local heating to industrial chemicals to long-distance transport

Solutions from FLDT aim to help expand the possibilities of what has been possible so far. The spectrum of possible applications ranges from local H2 production to long-distance transport for a global CO2-neutral hydrogen cycle economy. The HyRegio® process provides biogenic hydrogen regionally. CML4® enables the provision of green H2 for diverse applications in the hydrogen economy.

We take the existing, add our own to it, to let the new arise

In our process, we draw on existing plants (e.g. biogas plants) and existing infrastructure (e.g. natural gas network or LNG transports). Proven technical know-how (e.g. Synthetic Natural Gas or PtG technologies) is complemented by proprietary developments (e.g. plasma reactor) to arrive at innovative business models. Our solutions are flexible and can be further developed in line with changes in the energy market.

Through extended sector coupling — additional solution options for CO2 — immobilization (add-on)

In addition, there are further solution options through extended sector coupling. Sectors such as biofuels, the heat market, electricity, fuel cells (FCEV), refineries / chemicals or cement and steel industry can thus open up additional opportunities for CO2 immobilization.